The answer to how gravel is made depends on whether you are looking at the natural weathering and erosion process or manufactured crushed stones. We will discuss both the two ways.

Furthermore, to help clarify things for you, we will look at how gravel is made, tell you what it is, and compare the two types while giving a few examples.

Contents

What is gravel, and how are they formed?

Gravel refers to rock fragments with particle sizes larger than sand naturally formed through weathering and erosion of other existing rocks. Usually, water carries the fragmented stones to the river, ocean, and lake beds.

As water transports them or the action of ocean ways, they rub and mill against each other or other rocks stones, making their surface smoother edges and more or less round. This is how gravel, including river rocks and pea gravel, is made.

According to the Udden-Wentworth scale, typical gravel diameter or size range from granules that are 2mm to 4 mm (0.079-0.157 inches) to pebbles with 4mm to 64 mm (0.2-2.5 inches) to cobblestones measuring 64mm to 256 mm (2.5–10.1 inches) to boulders (larger than 10.1 inches).

On the other hand, ISO 14688 classifies rocks into fine gravel with diameters that are>2mm ≤ 6.3mm>, medium 6.3mm ≤ 20mm, and coarse with diameters of >20mm ≤ 63mm.

You have an idea of how gravel is made. That is not all. You deserve to know that these rocks are harvested from the sea, ocean, river, lake beds, and banks. Also, some exist on a plateau, i.e., plateau gravel formed before the present valleys existed.

One fantastic thing about gravel is that it naturally sorts according to its size, chemical and physical durability due to prolonged weathering and long transportation. However, gravel may at times fuse to form conglomerates, a kind of sedimentary rock.

Due to its appeal (round, smooth appearance), gravel has applications in landscaping and decoration. However, it has applications in construction too, but only accounts for a small percentage.

Some of the gravel examples include the following:

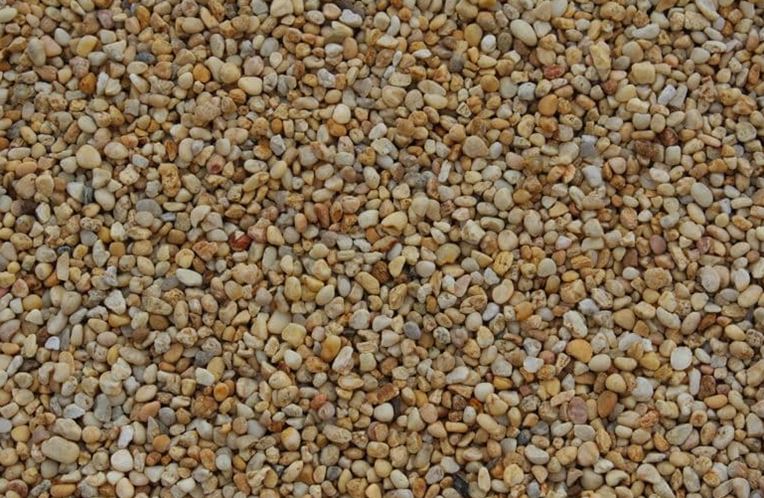

1. Pea gravel

Pea gravel is the most common gravel that measures about ⅜ of an inch. The name pea comes from the rock size, i.e., it closely resembles that of pea (leguminous plant).

Their smaller size and smooth, almost round surface make them perfect for topdressing dog runs, patios, walkways, playgrounds, and so on. You also have them in fish tanks, drainage projects, and so on.

2. River stones

They measure between 1 to 2 inches, come in various colors. Typical uses include lining creek edges or ponds, walkways, and driveways. Also, they are perfect for mulching, erosion control, and drainage systems.

Their larger size makes them unsuitable for use on walkways or dog runs since they are uncomfortable to walk on.

3. Jersey shore gravel

Jersey shore gravel is more or less the same as pea gravel, i.e., about ¾ inches in diameter, and has similar applications. What makes it stand out is the lovely yellow stone color with some gold, white and tan.

Note

in many parts of North America, gravel doesn’t just refer to naturally formed rocks with smooth edges but to any stone, including crushed rocks coarser than sand but smaller than 2 inches in size.

Crushed stones manufacture

Since crushed stones that are less than two inches are also gravel in North America, we have also to tell you how crushed rocks are made.

Due to the unavailability of sufficient gravel and some undesired properties such as not compacting well, people manufacture crushed stones, which, as the name suggests, are artificially broken down.

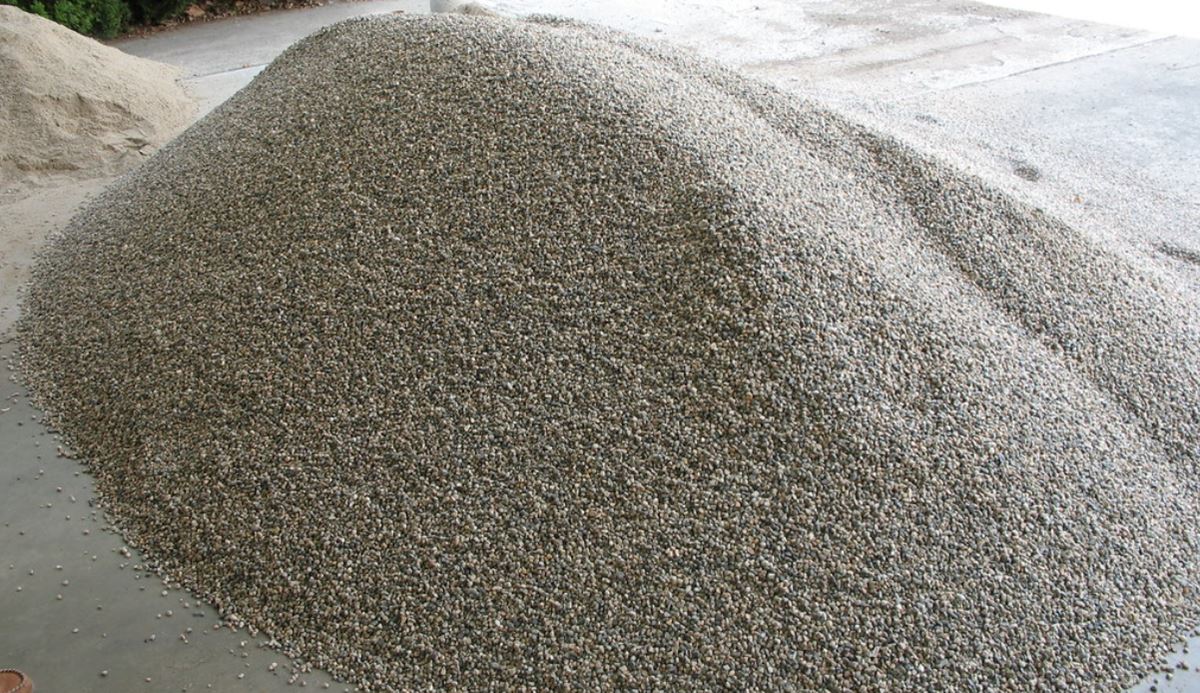

Crushed rocks are quarrying products whose manufacture involves mining or cutting huge boulders and transporting them to crushers.

These stones are then fed to primary crushers such as the jaw, and gyratory crushers break the larger rocks into smaller ones. The smaller rocks move to secondary and tertiary crushes, further breaking them down to smaller pieces or gravel.

The resultant crushed stones go through vibrating screens for sorting or grade them according to size. Different sizes have different applications. Any rocks that are still large will go back for second crushing.

One distinguishing feature of crushed stones is their angular shapes and jagged edges. While it makes them unsuitable for paving walkways (they are uncomfortable to walk on), they pack and lock better and don’t move much.

Some of the primary uses of crushed rocks include building and construction (making concrete, asphalt concrete, subbases, etc. However, some, especially those with fancy colors, have applications in landscaping or as decorative garden stones.

Which rocks are crushed?

The most crushed rock in the USA is limestone, a sedimentary rock due to its wide availability and softness (easy to crush). Others are granite, dolomite and trap stones (basalt, peridotite, gabbro and diabase).

Also, you will find the following crushed stones, but they are not so famous:

- Slate

- Sandstone

- Quartz

- Marble

- Scoria

- Quartzite

Colors

The color of crushed stones or gravel you will have depends on the color of the parent rock. Therefore, expect any color, including off-white, blue, gray, green, tan, buffs, purple, brown, and so on.

However, rare colors often attract higher prices as opposed to predominant ones.

Some of the popular crushed stones include the following:

Crushed stone #3

Crushed stones #3 measure about ½ to 2 inches wide. They have various applications at home and in construction, such as drainage projects, driveway bases, septic systems bases, and expensive projects such as railroads, culvert ballast, and roads.

Crushed stone #10

Also known as stone dust, rock screenings, gravel screening, or just screenings, crushed stones #10 is ⅛ of an inch or less. They are used to make concrete pavers and blocks, the base for pavers, among other uses.

Crushed stone #57

Stone #57 has stones with a diameter of ½ to 1 but mostly ¾ inches. They are workable by hand and have numerous roles, from making concrete mixes and hot-mixed asphalt, French drains, landscaping, retaining walls, topdressing driveways, walkways, and pathways.

Crushed stone #67

They are slightly smaller than stone 57, smaller than ¾ with typical sizes ranging from ½″ to ¾″. Some of the uses of crushed stones number 57 include retaining walls, slab and road base, stabilizing hard to compact soil, etc.

Crushed stone #411

They have the same size as stone #57. However, they also have some of the screening or stone dust created during the crushing process. Typical uses include in paver and wall bases, as compactible fill, on driveways, parking lots, and require compression.

Leave a Reply